| I

have choosen this Technical Enameling information from various sourses

that I think is pertinent for this class.

I will demo and discuss most of this information

in class and I demonstrate the various enameling processes.

What

is Enamels

Here are some of the enameling techniques used and taught

in classes at John C. Campbell Folk School in Brasstown North Carolina.

Cloisonne

Pilque-o-jour

Grisalle

Basse-Taille

Champleve

What is mesh size?

80 mesh enamel is the standard particle size available to our customers

unless specified otherwise. 80 mesh is glass ground to a particle size

which is slightly finer than granular sugar. It is normally applied by

sifting, but can also be mixed with water and inlayed or charged onto

to the substrate surface.

80 mesh means there are 80 openings in a standard wire

mesh screen per linear inch. 40 mesh means there are 40 openings in a

standard wire mesh screen per linear inch. We suggest using a 40 mesh

screen in our sifters to apply base coats of 80 mesh enamel to metal or

glass substrates.

6/20 mesh enamels are particles that have an average

diameter of about 1/16” to 1/8”. These particles are ideal

for bead making. Lump enamels (unground, unscreened enamels sometimes

referred to as ‘frit’) are particles that range from 1/16”

to 1” diameter chips or lumps. A variety of painting and liquid

enamels are also available for specific substrates.

What should I know about how to safely use Thompson

Enamel products?

All of Thompson’s enamel products are glass of one form or another.

Care should be taken not to ingest them. These products, however, can

be used quite safely if you adhere to the following housekeeping and hygiene

rules:

Rule 1. Keep products out of reach of children and pets.

Rule 2. Keep your work area neat and clean. Keep your clothing clean.

Rule 3. Use your enamels in a well ventilated work area. Wear a protective

dust mask if you are working with fine enamel powders for an extended

period of time, especially when sifting enamels.

Rule 4. Wash your hands prior to eating. Do not smoke or handle food when

you are working with enamels.

Rule 5 Assume everything by the Kiln is HOT

Please call 859-291-3800 if more specific information

on any particular product is required.

What is enamel?

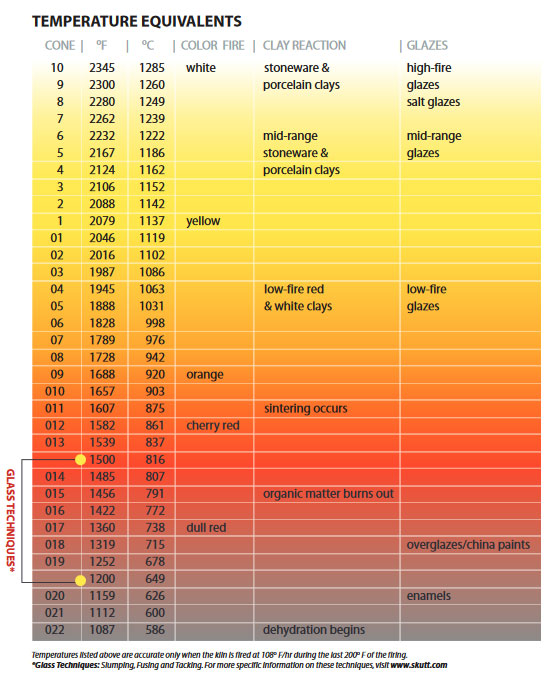

In general terms, vitreous enamel, porcelain enamel, copper enamel and

jewelry enamel all refer to the same thing. Enamel is a glassy compound

applied to and bonded by heat (fusion) to a metal surface; to a copper

surface at 1450 degrees F., and to a glass surface at 1100 degrees F.

to 1500 degrees F.

The most common glass is a fusion of silica, soda, lime,

and a small amount of borax. Though normally transparent, various amounts

of opacity can be produced by adding or growing crystals within the glass

structure. A wide range of colors are produced by incorporating certain

elements, mostly transition metals.

The physical properties of glass can be controlled to

permit bonding to most metals, for example, gold, platinum, silver, copper,

steel, cast iron and titanium.

The word ‘Enamel’ refers to the glass material

as well as to the finished product.

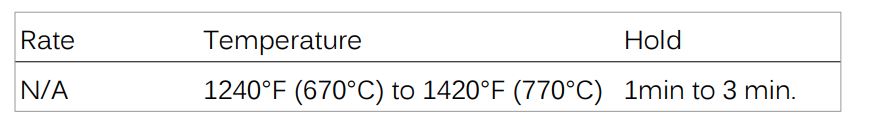

How is it done?

Enamel (glass) is crushed to a powder somewhat finer than granulated sugar

and somewhat coarser than flour. This powder is applied, by one of several

methods, to the metal or glass surface. Next the article is heated to

1100 to 1500 degrees F., either in a pre-heated furnace, a hand held torch,

or for enamels fused to glass, in a kiln. For metal, in a preheated furnace

the article may be fired from 1 to 5 minutes, depending on size or technique.

The article is removed and allowed to cool to room temperature. Subsequent

coats, normally different colors are applied. Sometimes many firings are

required to bring about the desired results. For fusing enamels to glass,

the article is placed into a room temperature kiln and the heat is brought

up according to the appropriate firing schedule to the maturation temperature,

then brought down to an annealing temperature and held there for a period

of time to relieve stresses in the glass, then brought back down to room

temperature before removing the article.

Different Flux Characteristics.

2008 – A low expansion clear used as the base coat

for the crackle technique when Liquid Form-Water Base enamels are used

for the second coat. 2008 is also good as a cover coat when working on

titanium white steel panels.

2009 – This soft fusing clear will clear up on copper on the first

firing. It may produce “break up” or “pull through”

when a subsequent coat of enamel is fired high.

2010 – This soft fusing clear will clear up on copper on the first

firing but requires more time and/or temperature than 2009. It may produce

“break up” or “pull through” when a subsequent

coat of enamel is fired high.

2015 – This medium fusing clear has a gold color similar to Thompson

lead bearing 1005 or 426. It works well under warm colors.

2020 – This clear does not “yellow” on silver. It should

always be used when a clear enamel is needed on silver as the first coat.

It may also be used on copper and gold. It is also the clear transparent

that is suggested to be used as a final cover coat in that is has a lower

expansion than most of the other transparent clears.

2030 – This clear is the best all-purpose-use clear. It works well

under other enamels, opaques and transparent's. Fire sufficiently to dissolve

all copper oxide (reddish-brown color). One or two re firings may be required.

2040 – This clear is harder than the above transparent clears. It

is least likely to develop “pull through” when applying subsequent

applications of enamel. It should be fired sufficiently to dissolve all

copper oxide.

How are enamels applied to metal?

80 mesh enamels are applied by sifting through a

sifter (a cup with handle and mesh screen in the bottom of the cup). A

sifter with a 40 mesh screen is used to apply 80 mesh base coats to metal

or glass.

A sifter with a 100 mesh screen in the

bottom of the cup is preferable when applying enamel through a stencil.

Some sifting stack screens filter out larger enamel particles so smaller

grains go through a 100 or 200 mesh sifter.

When sifting enamel, sift around the

outer edge of an object first, then move toward the center. The bottom

of the sifter should be completely covered with enamel for a more uniform

sift. A holding agent such as Klyr-fire used in a sprayer that can create

a fine mist will be required when coating a 3-dimensional object. It is

best to apply alternating thin coats of spray, then enamel, then spray,

then enamel, until an even coat has been achieved. If using a water based

holding agent, the water must be dried before firing.

Enamel may also be applied by wetting

with water and spooned onto a substrate surface or with use of a spreader

or fine sable brush. This is how the Cloisonne, Champlleve, or Acid Etched

cavity techniques are accomplished. The trick to successful wet inlay

(wet charging or wet packing) is to keep the enamel saturated with water.

Too much water or too little water and the enamel is not manipulable.

Water may need to be added or wicked out with a paper towel while working.

The work is 100% dried before firing.

If water is used in enamel applications as mentioned

above, the metal first should be degreased with a surfactant. The easiest

method is to heat copper until it flashes with color (annealing to green)

but not so long to create black copper oxide. Using Penny Bright is another

method of degreasing the copper.

It is important that the primary coat of enamel be as

complete and as perfect as possible for the first firing. Faults in the

enamel are not easy to correct after the enamel has been fired in place.

Unless fire-scale is meant to be part of the design, a sufficient amount

of enamel should be applied so that burned out areas do not occur. However,

thin coats are better than thick coats. More enamel may be reapplied if

the coat is on the thin side, but too much enamel is a bigger problem.

Too thick of an application may result in the enamel popping off. As you

continue to practice enameling, you will learn what is too little and

what is too much. It is important to note that enamel, when properly applied

and fired, does not flow out, but rather pulls in toward the greater mass

unless gravity affects the movement. If the enamel pulls away from the

edge after firing, the cause could be too heavy enamel application.

We suggest that both sides of the metal are enameled.

Counter enamel is sold as a mixture of colors, however any enamel may

be used as counter enamel. Counter enamel is applied to reduce stress

exerted on the enamel by the metal after the piece is cool or during cooling.

Counter enamel literally equalizes or counters the pull of the metal on

the enamel. The thickness of the metal and the thickness of the enamel

are relative in this matter. As the enamel thickness increases, the support

thickness must also increase unless other structural considerations have

been made in the metal.

Painting Enamels are much more finely

ground. They may be combined with a painting medium and applied with a

brush. Painting enamels are generally applied to a pre-fired enamel surface.

Liquid Form, Water Base Enamels are

formulated to be applied by spraying, dipping or pouring. These liquid

enamels have clay in them. The clay allows the coating to ‘set’

after application. If applied with a brush, brush marks may occur.

Liquid Form Brushable Enamels are formulated

to be applied with a brush. These enamels can be applied directly to metal

or on top of other enamels. Some like to sift a little 80 mesh powder

into the wet applied brushable enamel. When the brushable enamel is dried,

the surface is quite handleable which allows one to then enamel both sides

for the first firing. This is especially helpful to reduce warping when

enameling thinner gauges of copper.

Questions to ask if there is creaking or enamel

from metal separation.

Has the piece been counter enameled?

How does the thickness of the front enamel compare to the back enamel?

What metal is used?

If an alloy, be very specific as to the alloy.

What size and shape is the piece?

What is the metal thickness?

Is the base metal where the enamel is applied exactly uniform in thickness?

Is the piece flat or domed?

Is the piece cast, metal clay or from sheet?

If cast or metal clay, was the piece designed to be enameled?

Does the enamel have a starting and stopping place i.e. the edge of the

metal or a 90 degree angle recess in the metal.

If a recess for the enamel has been created, what is the recess’s

depth (for jewelry pieces depth should be .03 to .05 mm deep).

What enamel technique(s) is/are being used?

What is the method of application of the enamel?

How does the thickness of the enamel compare with the thickness of the

metal?

What equipment is being used to fire the piece – a torch or furnace?

What is the firing temperature?

What is the length of the firing time?

How long is the piece left to cool?

Where are the cracks in relation to the shape of the piece, cloisonné

wires, other inclusions?

What kind of enamel is being used?

What was the temperature of the furnace when the piece was inserted into

the firing chamber?

Has the piece been left out (say in the car) in freezing temperatures

then warmed up?

Wikipedia's

more than you probably want to know about every aspect of Enameling. |